DriveSaver Installation Instructions

Step 1 Step 1

-

With boat in the water, loosen hardware (do not remove) connecting propeller flange and reverse gear flange sufficiently so that alignment of engine can be checked using a feeler gauge. Bolts should remain loosely connected during alignment to support the propeller flange. Align engine installation to .005” maximum by adjusting engine mounts.

-

After successful alignment, completely disconnect propeller flange from reverse gear flange supporting dead weight of propeller flange.

NOTE: Shaft may have to be cut and the keyway re-machined to compensate for the thickness of the DriveSaver®.

Step 2 Step 2

-

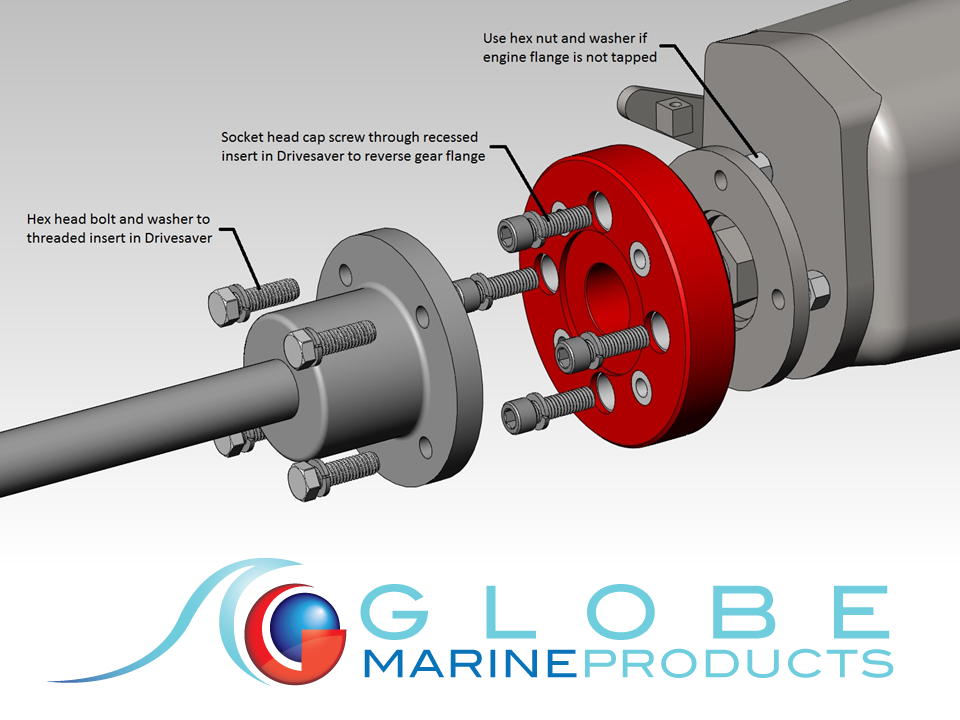

Install DriveSaver® to reverse gear flange by mating male pilot of Drivesaver® with female pilot of flange.

-

Rotate Drivesaver® to align socket head bolts with bolt holes of reverse gear flange.

-

Install socket head bolts using lock washers and nuts provided. Use small amount of waterproof grease to lubricate and protect inserts. Tighten in a “Z” pattern to torque ratings listed below.

NOTE: Some DriveSaver® models may have studs to attach to propeller flange. Install using lock washers and nuts provided, tighten in “Z” pattern to torque specifications listed below.

Step 3 Step 3

-

Slide propeller shaft and flange forward to mate with female pilot of Drivesaver®. Insert hex head bolts with lock washers into threaded inserts of Drivesaver®.

-

Use small amount of waterproof grease to lubricate and protect inserts. Lightly hand-tighten in a “Z” pattern to adequately support flange.

-

Use a dial indicator on propeller shaft directly behind flange to determine runout. Tap on outside of flange or Drivesaver® to bring installation as close to .005” TIR as possible. Finish tightening in a “Z” pattern to torque ratings listed.

After Installation After Installation

-

Recheck torque and alignment of shaft after 10 to 15 hours of operation.

-

If a bond is desired, use a piece of strip copper, punched for bolt size between offsetting inserts.

-

For models requiring a bushing kit, install bushing in flange hole before mating Drivesaver® to flange.

-

Bushing may be cut to length to fit flange.

Recommended Torque Specifications

|

|

25 ft-lb

|

35 ft-lb

|

55 ft-lb

|

110 ft-lb

|

200 ft-lb

|

|

|

303*

|

504

|

5756

|

908

|

1058

|

|

|

354*

|

504AC

|

5756A

|

908A

|

1058PR

|

|

|

353

|

504H

|

5756APR

|

908AC*

|

1108

|

|

|

404

|

504HPR

|

5756AZF

|

908PR

|

1108A*

|

|

|

357*

|

504PR

|

5756PR

|

908S

|

|

|

|

404A

|

4756

|

8010Z

|

908SPR

|

|

|

|

404AC

|

4756A

|

8010ZPR

|

7256

|

|

|

|

404V

|

4756APR

|

|

7256PR

|

|

|

|

404S*

|

4756PR

|

|

7258ZPR

|

|

|

|

424*

|

6256*

|

|

7306Z

|

|

|

|

424Y

|

6256PR

|

|

8078Z

|

|

|

|

454

|

|

|

|

|

|

|

504A

|

|

|

|

|

|

|

504APR

|

|

|

|

|

|

|

524Y

|

|

|

|

|

|

|

554

|

|

|

|

|

|

|

554PR

|

|

|

|

|

* Discontinued

|